What’s the Molybdenum disulfide ?

Molybdenum disulfide (MoS2) is an important solid lubricant, known as the “king of solid lubrication”

1. Molybdenum disulfide is a solid powder made from natural molybdenum concentrate powder after chemical purification.

2. The color of the product is black and slightly silvery gray, with metallic luster, and it feels slippery when touched, and is insoluble in water.

3. The product has the advantages of good dispersion and non-binding. It can be added to various greases to form a non-binding colloidal state, increasing the lubricity and extreme pressure of the grease;

4. It is also suitable for high temperature, high pressure, high speed and high load mechanical working conditions, and extends the service life of the equipment;

5. The main function of molybdenum disulfide used as friction material is to reduce friction at low temperature, increase friction at high temperature, and reduce ignition loss.

Application of molybdenum disulfide (MoS2)

1. Lubrication under wide temperature conditions: the applicable range of lubricating oil and grease is about 60 ° C to 350 ° C. Molybdenum disulfide solid lubricant can be applied to Operating temperature range from 270 ° C to 1000 ° C.

2. Lubrication under heavy load conditions: generally, the oil film of lubricating oil and grease can only bear relatively small load. Once the load exceeds the limit value it can bear, the oil film will break and the friction surface will bite. The average load that solid lubricating film can bear is 108Pa.

3. Lubrication under vacuum conditions: under high vacuum conditions, the evaporation of lubricating oil and grease is relatively large, which is easy to damage the vacuum environment and affect the working performance of other components. Molybdenum disulfide solid lubricating material is generally used for lubrication.

4. Lubrication under radiation conditions: Under radiation conditions, general liquid lubricants will polymerize or decompose and lose their lubricating properties. Solid lubricants have good radiation resistance.

5. Lubrication of conductive sliding surface: For example, the friction of conductive sliding surface, such as electric brush of electric motor, conductive slider, solar collector ring on artificial satellite working in vacuum and sliding electric contact, can be lubricated with composite materials composed of carbon graphite or metal.

6. Circumstances with very bad environmental conditions: In severe environmental situations, such as transportation machinery, engineering machinery, metallurgical and iron and steel industry institutions, mining machinery and other transmission parts working in dust, sediment, high temperature and humidity and other harsh environmental situations, molybdenum disulfide solid lubricant can be used for lubrication.

6. Corrosive environment: For example, the transmission parts of marine machinery and chemical machinery work in water (steam), sea water, acid, alkali, salt and other corrosive media, and they must undergo different degrees of chemical corrosion. Molybdenum disulfide solid lubrication can be used for transmission parts working in this situation.

7. Places with very clean environmental conditions: transmission parts in machinery such as electronics, textiles, food, medicine, paper making, printing, etc. need to avoid pollution, and MoS2 solid lubricant can be used for lubrication.

8. Circumstances without maintenance: some transmission parts do not need maintenance, and some transmission parts need to reduce maintenance times in order to save costs. In these occasions, the use of MoS2 solid lubricant is reasonable, convenient and can save money.

Molybdenum disulfide characteristics

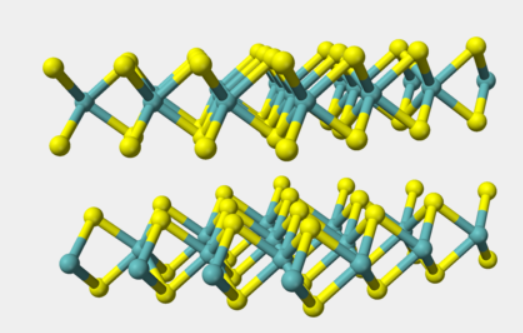

Molecular composition of MoS2: S=Mo=S

MoS2 density: 4.5 – 4.8 g/cm ³

MoS2 CAS No.: 1317 -33-5

MoS2 Mohs hardness: 1-1.5

MoS2 friction coefficient: 0.03-0.05

MoS2 temperature resistance range (atmospheric environment): – 180 ℃ – 400 ℃

MoS2 compression resistance: about 30000 kg/cm ²

Chemical stability of MoS2: it has strong corrosion resistance and has no effect except nitric acid, aqua regia and boiling hydrochloric acid.

Post time: Mar-08-2023